Precision in Pipeline Preparation: Exploring Pipe Beveling Tools and Equipment

Pipeline fabrication and safeguarding involve strict attention to fine points, particularly when preparing pipes for welding jobs. The significant preparatory measures include beveling as the rims are being reduced to ensure seamless welding joints. In this you will know the domain of pipe beveling equipment and supplies, touching on the aspects of its value and function and providing examples in vast industries.

Understanding Pipe Beveling

Pipe beveling is a very powerful method that is necessary to get strong and durable welds in pipelines. This involves the formation of a sloped floor surface in order to make it possible for the right fusion between pipes or fittings. The angle typically is what matters. Beveling assists in spreading welding heat evenly, avoiding surface irregularities and drilling holes, thus improving weld strength and weld joint integrity.

The Importance of Using Pipe Beveling Tools

A pipe beveling machine is taken as a tool, crafted with the intention of making the process of beveling more effective and efficient. They vary from hand-powered tools to computerized stuff, made in accordance with the specific needs and objectives they were to pass. The main aim of these tools is to provide the mandatory accuracy, productivity and reproducibility in pipe fabrication so that the rework is reduced and productivity is increased.

Automated Pipe Beveling Equipment

Several large-scale pipeline businesses and extensive factories would have no other option but to select automated pipe-beveling machines. These brand-new generation machines are equipped with the latest technologies and automation in the form of robotics, which results in the business being able to achieve high accuracy and consistency on a large scale.

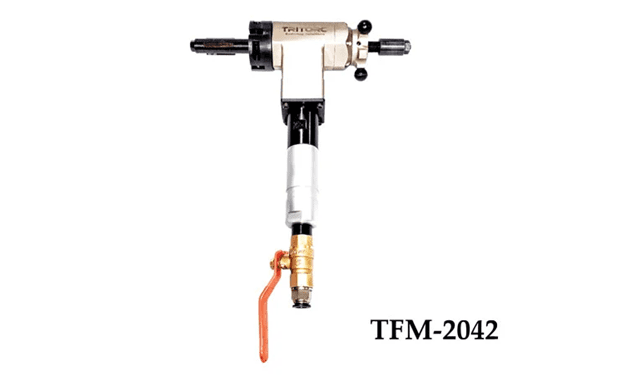

Handheld equipment for pipes can be cut out into an array of shapes, as well as a portable machine for field application and workshop bench equipment. Such devices are fitted with ultra high-precision circular saws, which are infinitely adjustable and self-tensioning and also offer many parameters that provide a wide range of dimensions and sizes of the pipe.

Applications Across Industries

A pipe beveling machine with its tools has many targeted industries, including oil and gas, shipbuilding, manufacturing, and many others. Pipes are bevelled by machines in the oil and gas industry, and those in construction, repair of pipelines, or maintenance use them as well. This objective aims to safeguard the quality and credibility of the essential services underpinning the stability and functioning of society.

In the field of construction, pipe beveling gear is used in plumbing and HVAC installations. In the installations, it is very important to have precise fittings and weld joints for the efficiency of the fluid flow and structural integrity. Likewise, in shipbuilding and production, this equipment is integral in making the pipes of vessels, units of equipment, and devices to specification and safety guidelines.

Conclusion

Pipe beveling tools and machinery are the spearheads of precision engineering and business performance and efficiency in pipeline fabrication. Whether handheld for versatility and mobility or automated machines for mass production, these tools occupy a crucial place in the pursuit of pipelines across diverse disciplines and corporations, notwithstanding the context. The skills and complexity of the pipe beveling equipment will be adjusted to the advancing demands of the period. Thus, innovation and progress in pipeline manufacturing and protection will take place.